In the world of industrial machinery, the choice of materials for bushings plays a crucial role in ensuring optimal performance, reliability, and longevity. Junty’s alumina bushings stand out as a testament to innovation and excellence, offering unparalleled customization options and advanced ceramic technology. Let’s delve into the advantages of alumina bushings and explore how Junty‘s customizable solutions provide optimal protection for shafts in challenging environments.

Understanding Alumina Bushings

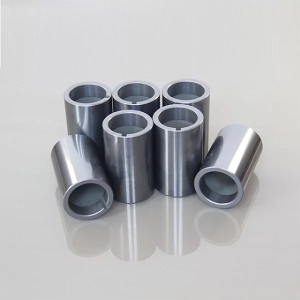

- Role: Alumina bushings, also known as shaft-protecting sleeves, are cylindrical components designed to support and guide rotating shafts within machinery. They provide a protective barrier between the shaft and the surrounding components, minimizing friction, wear, and damage.

- Material Properties: Alumina, or aluminum oxide, is a high-performance ceramic material known for its exceptional hardness, wear resistance, and thermal stability. It offers superior mechanical strength, chemical resistance, and electrical insulation properties, making it ideal for demanding industrial applications.

Advantages of Junty’s Alumina Bushings

- Unparalleled Customization: Junty’s alumina bushings offer unparalleled customization options, allowing customers to choose from advanced ceramic materials such as Silicon Carbide (SSiC/SSiC+C), Alumina (97%CE/99%CE/99.5%CE), Zirconia, Tungsten Carbide (Nickel bonded or Cobalt bonded), and Carbon Graphite. This versatility enables customers to select the most suitable material for their specific application requirements, ensuring optimal performance and durability.

- Advanced Ceramic Technology: Junty’s alumina bushings utilize advanced ceramic technology to provide superior protection for shafts in challenging environments. The fusion of high-performance ceramic materials with innovative bushing designs ensures maximum durability, reliability, and longevity, even in harsh operating conditions.

- Optimal Shaft Protection: By choosing Junty’s alumina bushings, customers can rest assured that their shafts are well-protected against mechanical, chemical, and environmental damage. Whether it’s handling corrosive fluids, abrasive particles, or high temperatures, Junty’s customizable solutions provide optimal protection, minimizing wear and extending equipment lifespan.

Conclusion

In conclusion, Junty’s alumina bushings offer unmatched customization options, advanced ceramic technology, and optimal shaft protection for demanding industrial applications. Trust Junty to provide innovative solutions tailored to meet your specific needs and requirements, ensuring superior performance, reliability, and longevity for your machinery and equipment. Contact Junty today to experience the difference in alumina bushing technology and elevate the performance of your industrial applications.