The RFID reader module will be covered in this blog. A device called an RFID module is used to read and store information from an RFID tag that is attached to a product or object. To keep track of inventory and make sure everything is put away, they are frequently employed in automated warehouses. You will learn about the advantages of this cutting-edge technology in this post, as well as how to select it for your unique requirements.

The advantages of using an RFID reader module

A tool that can be used to read and store data from an RFID tag is an RFID reader module. Using an RFID reader module in an automated warehouse has various advantages, including the ability to track inventory, automate processes, and boost productivity.

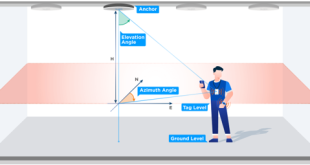

RFID tags are becoming more and more common in the field of inventory control. They differ from conventional barcodes in a variety of ways, including the capacity to hold more data and the capacity to read from a distance. They are therefore perfect for use in automated warehouses where inventory needs to be continuously monitored.

In an automated warehouse, an RFID reader module can aid in task automation. For instance, the RFID reader module can be used to automatically identify the contents of a pallet of products when it enters the warehouse, updating the inventory records of the warehouse as a result. For the people who work in the warehouse, this can save a ton of time and effort.

The effectiveness of an automated warehouse can also be increased by the deployment of an RFID reader module. Automation of processes like inventory management frees up staff time so they can concentrate on other responsibilities like order picking and dispatch packaging. This has the potential to significantly increase productivity.

How to pick the ideal module for your particular needs

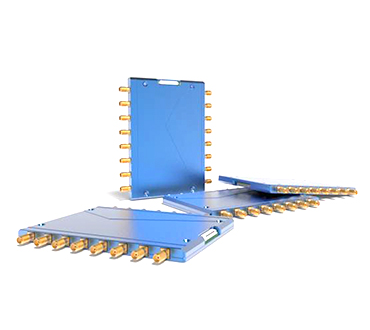

The RFID reader module is one of the most crucial pieces of equipment for automated warehouses. It is in charge of reading and decoding the RFID tags affixed to goods. The product is then tracked using this data as it moves through the warehouse and eventually arrives at its final destination.

When selecting an RFID reader module for your unique requirements, there are a few factors you should take into account. The frequency that you need to support comes first. RFID tags work at three different frequencies: low (125-134 kHz), high (13.56 MHz), and ultra-high (868-915 MHz). You need to confirm that your reader can handle the necessary frequency for the products you will be tracking.

The read range is the second item you should think about. This is the range at which an RFID tag may be reliably decoded by a reader. A number of variables, such as tag type, antenna type, and power output, have an impact on the read range. To identify the best read range for your application, you will need to test out various combinations of these elements.

Finally, consider the need for data processing and storage. You might require a module with integrated storage or one that can connect to an external storage system depending on how much data you intend to gather. Additionally, you will require a module with a CPU strong enough to handle those if you intend to perform any type of data processing locally.

Conclusion

An amazing technological advancement with the potential to completely change how warehouses are run is the RFID Reader Module. In addition to automating the inventory process, it also has the potential to boost precision and effectiveness. We think that this technology has a promising future and that it is definitely worth investing in. Welcome to learn Hopeland RFID whenever you want to learn more.