Basic hand tools

You cannot learn to use tools from a book, it is clearly a very practical skill. However, you can follow the recommendations made here and, of course, by the manufacturers. Even the range of basic hand tools is now quite daunting and very expensive.

And of course, as well as all these different types they are all available in many different sizes! It is worth repeating the general advice and instructions for the use of hand tools.

- Only use a tool for its intended purpose.

- Always use the correct size tool for the job you are doing.

- Pull a wrench rather than push it whenever possible.

- Do not use a file or similar, without a handle.

- Keep all tools clean and replace them in a suitable box or cabinet.

- Do not use a screwdriver as a pry bar.

Accuracy of test equipment

The first and second of these issues can be dispensed with by knowing how to read the test equipment correctly and also knowing the appropriate level of accuracy required. A micrometer for a plug gap? A ruler for valve clearances? I think you get the idea. The accuracy of the equipment itself is another issue.

Accuracy is a term meaning how close the measured value of something is to its actual value. For example, if a length of about 30 cm is measured with an ordinary wooden ruler, then the error may be up to 1 mm too high or too low.

Basic test meters

An essential tool for working on vehicle electrical and electronic systems is a good digital millimeter. Digital meters are most suitable for the accuracy of reading as well as their available facilities. The list of functions, which is broadly in order, starting from essential to desirable, should be considered.

The loading effect is a consideration for any form of measurement. The question to ask is: ‘Does the instrument change the conditions, so making the reading incorrect? With a millimeter, this relates to the internal resistance of the meter.

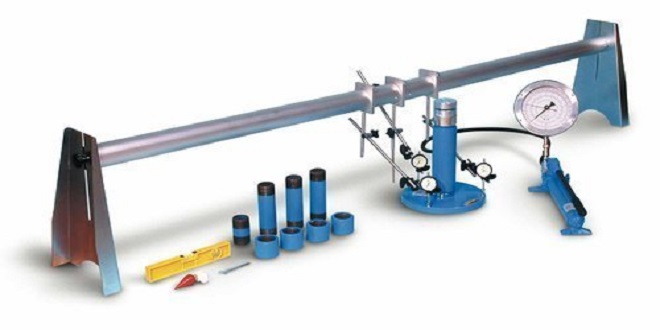

Pressure testing

Measuring the fuel pressure in a fuel injection engine is of great value when fault-finding. Many types of pressure gauge are available and often come as part of a kit consisting of various adapters and connections. The principle of the gauges is that they contain a very small tube wound in a spiral. As fuel under pressure is forced into a spiral tube, the tube unwinds causing the needle to move over a graduated scale.

Engine analyzers

Some form of engine analyzer has become an almost essential tool for fault-finding in modern vehicle engine systems. The latest machines are now generally based around a personal computer. This allows more facilities, which can be added to by simply changing the software.

Whilst engine analyzers are designed to work specifically with the motor vehicle, it is worth remembering that the machine consists basically of three parts.

Summary

Unfortunately, even though a common standard has been developed some manufacturers have interpreted it in different ways. However, it is now possible to access detailed information from many vehicle systems that until recently was only available to the main dealers.

Out of interest (and because I wanted one!) when I was writing this section (October 2003), I bought an interface and cable for about £40/$60 (I could have bought the parts for even less). Together with the software, I now have a powerful diagnostic tool – at a very reasonable price.