Have you been wondering about spc flooring production line? What is it, its types, and the most important is how to choose the right spc flooring production line for your needs? In this blog post, you will find all those answers and more.

What is the spc flooring production line?

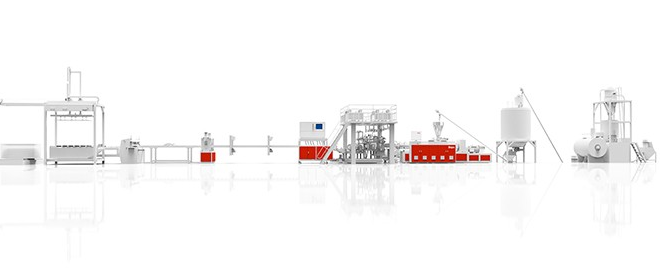

The Spc Flooring Production Line is a manufacturing process used to create flooring products. The line typically uses a series of machines to cut, shape, and lay down the flooring product.

Types of spc flooring production lines

When choosing an spc flooring production line, there are a few different types. Each type has its features, so it’s important to know what each one offers before deciding. Here are the most common types of spc flooring production lines:

- Continuous Production Line: A continuous production line is the most efficient type of line, as it can produce large quantities of product in a short amount of time. However, this efficiency comes at a cost, as continuous production lines are typically more expensive than other types.

- Batch Production Line: A batch production line is less efficient than a continuous line but is also less expensive. This line type is typically used for smaller production runs or products requiring more customization.

- Hybrid Production Line: A hybrid production line combines elements of both continuous and batch production lines. This line is often used for products requiring high volumes but also some customization.

- Flexible Production Line: A flexible production line is the most versatile type of line, as it can be configured to meet the specific needs of your product.

How to choose the right spc flooring production line?

There are a few factors to consider when choosing the right spc flooring production line for your needs. The first is the type of flooring you want to produce. There are two main types of spc flooring, solid and engineered. Solid spc flooring is made from a single piece of material, while engineered spc flooring comprises multiple layers of material. The type of flooring you choose will determine the type of production line you need.

The next factor to consider is the size of your production line. The size of your line will be determined by the amount of flooring you plan on producing each day. A smaller production line would be sufficient if you are only looking to produce a small amount of flooring. However, if you plan on producing large quantities of flooring, then you will need a larger production line.

Finally, you will need to consider the cost of the production line. The cost of the line will vary depending on the size and type of production line you choose.

Conclusion

With so many different spc flooring production lines on the market, it can be difficult to know which one is right for your needs. In this article, we have outlined some important factors to consider when making your decision. We hope that by taking these factors into account, you will be able to choose the spc flooring production line that is perfect for your business. If you still have no idea how to choose, Boyu Extruder should be worth your investment!